Brief about Rapid Prototyping

Rapid prototyping is a quick, iterative method of creating prototypes of a product or component to test its design and functionality before mass production. This process involves using computer-aided design (CAD) software and advanced manufacturing technologies, such as 3D printing, to quickly produce a physical model of the product. The goal of rapid prototyping is to identify and address design flaws early in the development process, saving time and reducing costs associated with making changes later in the production cycle.

What is the history of Rapid Prototyping?

Rapid prototyping, also known as 3D printing, is a technology that allows for the creation of physical objects from digital models. The history of rapid prototyping can be traced back to the mid-1980s when the first rapid prototyping machine was invented.

The first rapid prototyping machine, called the 3D Systems SLA-1, was introduced in 1986. It used a process called stereolithography, in which a laser was used to cure and harden a resin material layer by layer to create a 3D object. This technology paved the way for the development of other rapid prototyping techniques, such as fused deposition modeling (FDM), selective laser sintering (SLS), and others.

In the 1990s and 2000s, rapid prototyping technology continued to evolve and become more widely used in a variety of industries, including aerospace, automotive, medical, and consumer goods. The introduction of cheaper and more accessible rapid prototyping machines, combined with advancements in software and materials, made it possible for businesses and individuals to create prototypes and low-volume production parts in-house.

Today, rapid prototyping is a well-established technology that is widely used in product development and manufacturing. With the continued advancement of the technology, including the development of multi-material and multi-color 3D printing, rapid prototyping has become an essential tool for designers, engineers, and manufacturers around the world

What is the importance of Prototypes?

Prototypes are important in product design and development because they provide a tangible representation of an idea, allowing for testing, demonstration, and visualization of the product's features and design. Prototypes also facilitate communication between stakeholders, as they provide a common point of reference for discussing the design and functionality of a product. By testing prototypes, designers can identify and resolve potential issues early in the development process, saving time and resources. Additionally, prototypes can be used to validate the feasibility and marketability of a product before committing to full-scale production.

What are the different technologies available to make Prototypes?

There are several technologies used to make prototypes, each with its own strengths and limitations. Some of the most common rapid prototyping technologies include:

Stereolithography (SLA):

SLA uses a laser to cure and harden a photopolymer resin layer by layer to create a 3D object. This technology is well-suited for producing high-precision and highly detailed prototypes.

Fused Deposition Modeling (FDM):

FDM uses a heated extruder to melt and deposit plastic material layer by layer to create a 3D object. This technology is well-suited for producing prototypes that are strong, durable, and have a moderate surface finish.

Selective Laser Sintering (SLS):

SLS uses a laser to sinter and fuse fine powder particles layer by layer to create a 3D object. This technology is well-suited for producing prototypes with complex shapes and intricate details, and is often used to produce functional parts and end-use products.

Laminated Object Manufacturing (LOM):

LOM uses a laser to cut and laminate sheets of material, such as paper or plastic, to create a 3D object. This technology is suited for producing large prototypes with a reasonable detail and accuracy.

Multi Jet Printing (MJP):

MJP uses multiple jets to deposit a photopolymer material layer by layer to create a 3D object. This technology is well-suited for producing prototypes with high-resolution and smooth surface finishes, and is often used to produce parts with fine details and intricate geometries.

These are just a few of the most common rapid prototyping technologies, and there are many others. The choice of technology will depend on the requirements of the prototype, including the size, complexity, and material requirements.

Can Prototypes be made by CNC machining process?

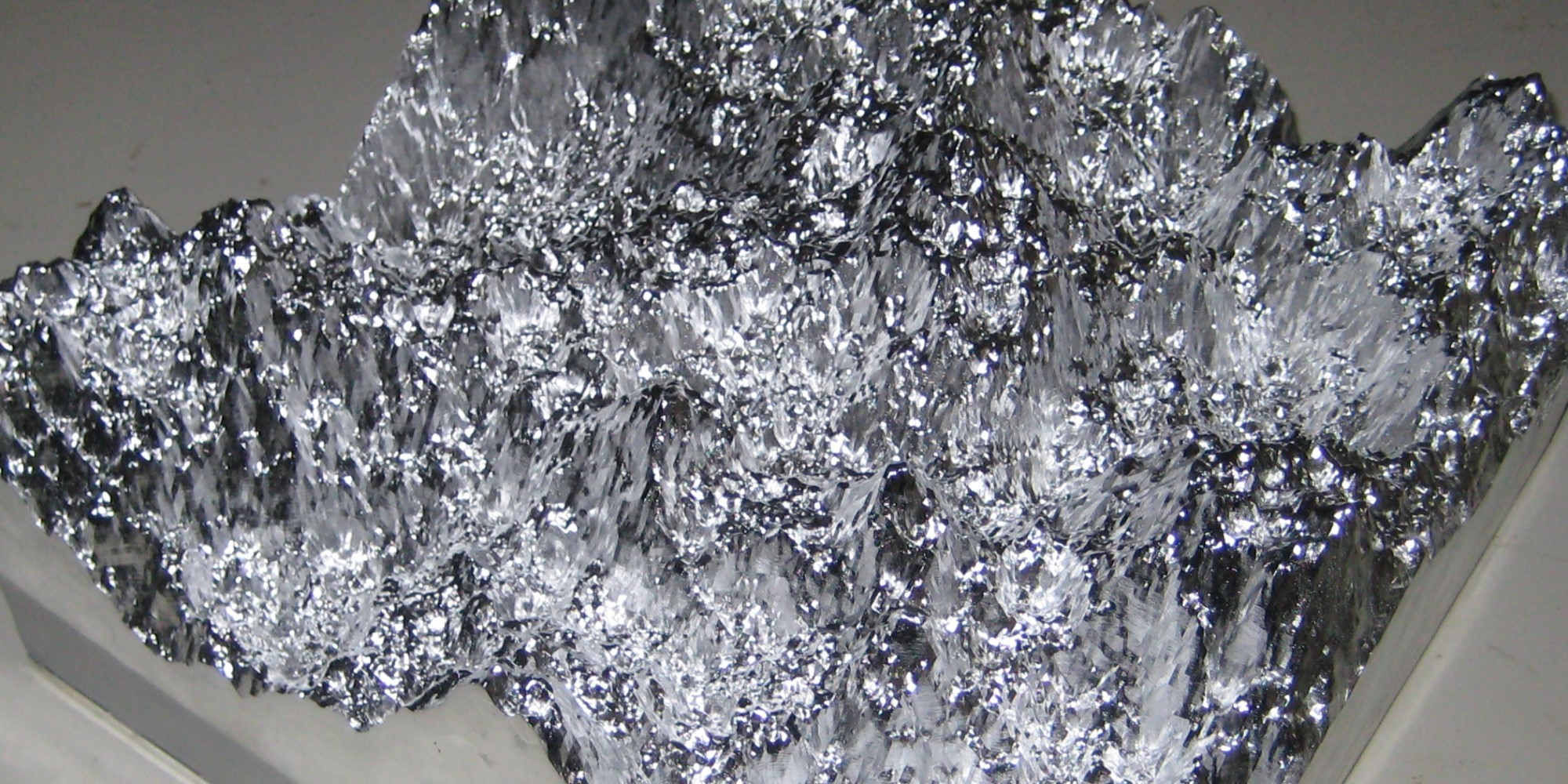

Yes, prototypes can be made using the CNC (Computer Numeric Control) machining process. CNC machining is a subtractive manufacturing process that uses computer-controlled cutting tools to remove material from a block of material (such as metal or plastic) to create a 3D object. This process is well-suited for producing prototypes and low-volume production parts with high precision and intricate details.

CNC machining can produce prototypes from a variety of materials, including metals (such as aluminum, steel, and titanium), plastics (such as ABS, polycarbonate, and POM), and composites (such as carbon fiber and fiberglass). The choice of material will depend on the requirements of the prototype, including the strength, stiffness, and dimensional stability requirements.

Overall, CNC machining is a popular and effective method for producing prototypes and low-volume production parts, and is often used in combination with other rapid prototyping technologies, such as 3D printing or injection moulding, to produce prototypes with a high level of accuracy and detail.

Can prototypes be used as Real Parts?

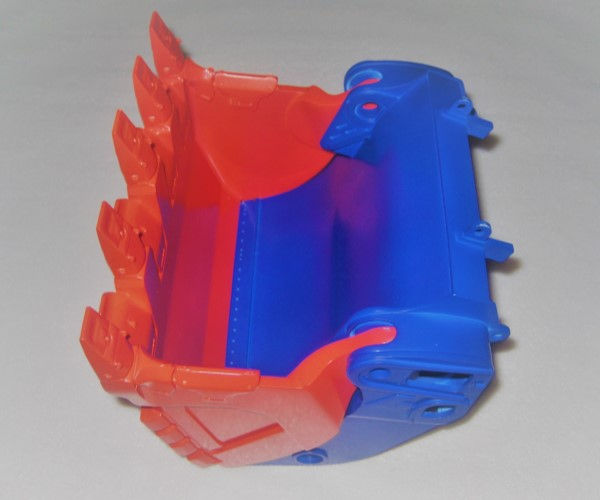

Short answer is Yes or No, prototypes can be used as real parts, depending on the purpose and level of detail of the prototype. Some prototypes are designed and fabricated to closely resemble the final product, with materials and manufacturing methods that are similar to those that will be used in mass production. These prototypes can be functional and can be used as real parts in some cases.

However, other prototypes are created for testing or demonstration purposes only and may not be suitable for use as real parts. These prototypes may be made with materials and manufacturing methods that are not intended for long-term use and may not have the same level of durability and reliability as the final product.

It is important to consider the intended use and requirements of a prototype before determining whether it can be used as a real part.

What determines the Prototype pricing?

The pricing of a prototype can be influenced by several factors, including:

1. Material:

The material used to produce the prototype can significantly impact the cost. For example, using a high-performance material, such as titanium, will typically be more expensive than using a more common material, such as ABS plastic.

2. Technology:

The rapid prototyping technology used to produce the prototype can also impact the cost. Some technologies, such as SLS or MJP, are more expensive than others, such as FDM.

3. Complexity:

The complexity of the prototype design can also influence the cost. Prototypes with intricate details or complex shapes may require more time and resources to produce, resulting in higher costs.

4. Quantity:

The number of prototypes being produced can also impact the cost. Producing a single prototype can be more expensive than producing multiple prototypes at once.

5. Lead time:

The time required to produce the prototypes can also impact the cost. Urgent requests for prototypes may require expedited processing, which can result in higher costs.

6. Location:

The location of the prototyping service can also influence the cost. Prototyping services located in areas with a high cost of living, or in regions with a high demand for rapid prototyping services, may charge more than those in other areas.

It's important to keep in mind that the price of a prototype is not the only factor to consider when choosing a prototyping service. Other factors, such as the quality of the prototype, the level of customer service, and the experience of the prototyping team, can also be important considerations.

What type of Finish can be applied on the Prototypes?

The type of finish that can be applied on prototypes depends on the purpose and requirements of the prototype. Some common types of finishes that can be applied to prototypes include:

1. Paint:

Paint finish can be used to simulate the final colour and texture of a product.

2. Powder coating:

A powder coating finish is a type of paint finish that is applied as a dry powder and then cured in an oven. This finish provides a hard and durable surface that is resistant to wear and tear.

3. Anodizing:

Anodizing is a type of electrochemical finish that can be applied to metal prototypes to provide a hard and durable surface that is resistant to wear and tear.

4. Plating:

Plating is a process that applies a thin layer of metal, such as gold or silver, to the surface of a prototype to provide a decorative finish.

5. Texturing:

Texturing can be applied to prototypes to provide a specific surface finish, such as a matte or glossy finish, or to simulate the texture of the final product.

6. Beadblasting:

Sandblasting or Beadblasting is a process that uses high-pressure air to blast abrasive particles against the surface of a prototype to create a specific texture or surface finish.

The type of finish that is applied to a prototype depends on the requirements of the prototype, such as the level of detail required, the materials being used, and the intended use of the prototype.

What are the advantages of Prototypes?

Prototyping has several advantages, including:

Testing and validation:

Prototyping allows designers and engineers to test and validate the design and functionality of a product before it goes into mass production. This can help identify and resolve any issues with the product before it reaches the market, saving time and money in the long run.

Concept visualization:

Prototyping can help bring a product concept to life, making it easier for stakeholders to visualize the product and understand how it will look and function in the real world.

Customer feedback:

Prototyping allows designers and engineers to gather feedback from potential customers and stakeholders, which can help refine the design and improve the final product.

Marketing:

Prototyping can be used as a marketing tool to help generate interest in a product and secure investment or funding for the development of the product.

Cost savings:

By using prototypes to test and validate the design and functionality of a product, designers and engineers can identify and resolve any issues before the product goes into mass production, which can help reduce the cost of production and minimize the risk of product failures.

Reduced development time:

By using prototypes to validate the design and functionality of a product, designers and engineers can reduce the time required to bring a product to market, as they can identify and resolve any issues with the product before it reaches the mass production stage.

Overall, prototyping is an important step in the product development process, as it allows designers and engineers to validate their ideas and ensure the product is functional and meets the requirements of the target market before it goes into mass production.

Which technology is better for Rapid Prototyping?

The "best" rapid prototyping technology depends on the specific requirements of the prototype, such as material, accuracy, surface finish, size, and volume. Here are a few of the most commonly used rapid prototyping technologies and the situations in which they are best suited:

Fused Deposition Modeling (FDM):

FDM is a popular and affordable rapid prototyping technology that uses a filament of thermoplastic material, which is melted and extruded through a nozzle to build up the prototype layer by layer. FDM is well-suited for producing prototypes with basic shapes and low-complexity geometries, and is often used for creating prototypes of plastic parts.

Stereolithography (SLA):

SLA is a rapid prototyping technology that uses a laser to cure liquid resin into a solid object, layer by layer. SLA is well-suited for producing prototypes with fine details and complex geometries, and is often used for creating prototypes of complex parts, such as medical devices, electronics, and consumer products.

Selective Laser Sintering (SLS):

SLS is a rapid prototyping technology that uses a laser to fuse together small particles of plastic, metal, or ceramic powder into a solid object, layer by layer. SLS is well-suited for producing prototypes with complex geometries and high strength and stiffness requirements, and is often used for creating prototypes of functional parts, such as gears and structural components.

Multi Jet Printing (MJP):

MJP is a rapid prototyping technology that uses a print head to jet droplets of material, which are then cured using UV light to build up the prototype layer by layer. MJP is well-suited for producing prototypes with fine details and complex geometries, and is often used for creating prototypes of complex parts, such as medical devices and electronics.

CNC Machining:

CNC machining is a subtractive manufacturing process that uses computer-controlled cutting tools to remove material from a block of material (such as metal or plastic) to create a 3D object. CNC machining is well-suited for producing prototypes with high precision and intricate details, and is often used for creating prototypes of metal and plastic parts.

Ultimately, the best rapid prototyping technology for a given project will depend on the specific requirements of the prototype, including the material, accuracy, surface finish, size, and volume requirements. A combination of different rapid prototyping technologies may be used to produce a single prototype, depending on the specific requirements of the prototype.

What is the future of rapid prototyping?

The future of rapid prototyping looks promising, with a continued focus on improving the accuracy, speed, and affordability of the technology. Here are a few trends and developments that are likely to shape the future of rapid prototyping:

Increased automation: The use of artificial intelligence and machine learning algorithms is likely to increase in rapid prototyping, enabling designers and engineers to automate the design and prototyping process, reducing the time required to bring a product to market.

Development of new materials: The development of new, high-performance materials for use in rapid prototyping is likely to continue, enabling designers and engineers to produce prototypes with improved strength, stiffness, and durability.

Growth of the 3D printing market: The global market for 3D printing is expected to continue to grow, driven by increased demand for rapid prototyping in a variety of industries, including aerospace, automotive, healthcare, and consumer goods.

Expansion of the use of rapid prototyping in production: The use of rapid prototyping in mass production is likely to increase, as companies look to leverage the technology to produce low-volume or custom parts, or to quickly produce replacement parts in the event of product failures.

Increasing use of multi-material prototypes: The ability to produce prototypes with multiple materials, including metal and plastic, is likely to continue to improve, enabling designers and engineers to create prototypes that more closely resemble the final product.

Integration with other technologies: The integration of rapid prototyping with other technologies, such as virtual reality, simulation, and the Internet of Things, is likely to continue, enabling designers and engineers to create more sophisticated and interactive prototypes.

Overall, the future of rapid prototyping looks promising, with continued advancements in the technology that are likely to make prototyping faster, more accurate, and more affordable for designers and engineers.

Conclusion

The role of rapid prototyping in the development of technological advancements in the industrial revolution is pivotal. It allows virtual simulation, experimentation, and realistic representation that have shaped our existing reality. On top of it, the potential is far more than we have realised until now. Along these lines, are you looking for high-quality and cost-effective rapid prototyping services? ArpTech offers custom-made aesthetic and functional prototypes to help you meet your exact requirements. These conditions can even range from design concepts to short-run production.