Importance of Rapid Prototyping in Architectural Industry

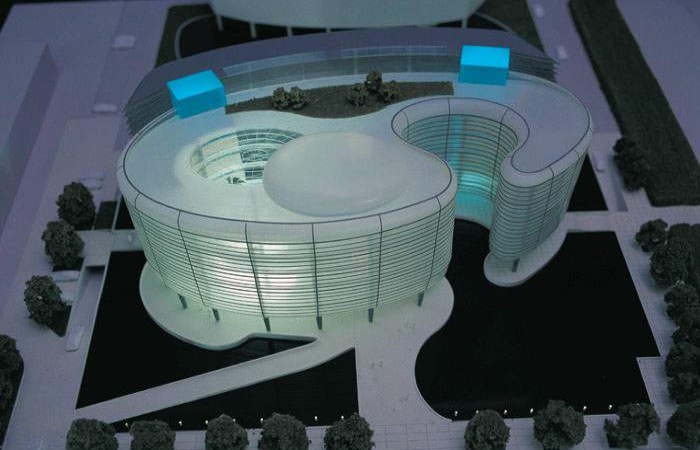

Rapid prototyping refers to quick manufacturing of a physical model, part, or assembly using 3D Computer-Aided Design (CAD). This approach has become instrumental for architectural engineers to check the validity and functionality before the product is produced or used on a large scale. At the same time, rapid prototyping for architects offers lucrative opportunities to check the sustainability of their prepared designs. It helps architects create architectural building scaled models by using various rapid prototyping materials and technologies.

Rapid Prototyping For Architects – How Is It Beneficial?

Unlike a simple product design, architectural designs are more spacious, sensitive, and require a more significant and improved safety factor. Nevertheless, all these requirements are hard to meet or analyse with a manual model or 2D drawings. Hence, rapid prototyping for architects allows architects to build a physical scaled model of their desired shape. They can use either additive or subtractive layer manufacturing techniques for that purpose.

Meanwhile, this physical model facilitates architects to analyse the architectural concepts of design. It also helps them to convey, to a wide range of society, before the construction project starts. That is how architects may explore and add new ideas to an existing design. They can also minimise development costs incurred for multiple iterations for perfection in design.

Commonly Adopted Method of Rapid Prototyping for Architects

When it comes to Architectural modelling, the one-size-fits-all approach may not provide the optimum solution. It is common practice to subdivide large scale project, such as multi-level building prototype, into segments. Then choose suitable RP Technology based on size and raw material availability. Various RP techniques like selective laser sintering (SLS), CNC machining, and stereolithography (SLA) can be used for prototyping. However, 3D printing is the most commonly used technology for building scaled models.

3D printing (additive manufacturing) is toward making a 3D object by creating a three-dimensional design on a computer. It then produces the design using a printer called a 3D printer. 3D printing empowers users to add another degree of detail that was beforehand impractical. While corresponding to architecture, designs representing theoretical architecture concepts can be acknowledged as tangible models.

Before approaching such modern techniques, suppose architects wanted to make physical interpretations of architecture models. In that case, they needed to go through a meticulous process. This old-fashioned process included utilising handmade methods and depending on craftsmanship to make intense assumptions about the final view of their idea. The manual process might be financially savvy. However, it was in exchange for time and quality. But then again, this all changed when rapid prototyping reformed the prototyping concept for architects. Its involvement can be gauged from the fact that people have now even created 3D-printed houses.

Going from Initial Design to Physical Model

Let's elaborate on the actual process of going from initial design to physical and tangible model.

Initial Design Phase

Each physical model starts with a design. It implies that the model needs to reflect a particular design solution for a specific architectural design project with particular parameters. The procedure typically begins as a rough hand sketch that might be refined by hand.

Schematic Phase

When the initial and underlying design sketches are done, they are then computerised in computer-aided design software. The digital model can be created through CAD software like Autodesk AutoCAD or 3D Max. Both software possesses the ability to interpret 2D images into 3D models. At this stage, it is still helpful to modify the design to make it acceptable.

3D Modelling Phase

It refers to the most critical phase of rapid prototyping for architects. Whatever drawings or models have been made in the schematic phase, they are interpreted, keeping in mind the objective achieved from the initial design phase. For example, does the building have to be transparent or solid? On the other hand, the scaling of the model is also performed in this phase. It may refer to the height of the ceiling, entryway, window size, and other comparable variables.

Other factors may incorporate the material property, detailing, and specifying the geometry. Besides, model strength, model support, digital model resolution can also be included. When all these things are done, the design is adjusted according to the requirement and ready to be printed.

Rapid Prototyping (3D Printing) Phase

It is the actual phase in which the design is converted into the physical model using 3D printers and CNC machines. The selection of colour is crucial for architectural models, which should be done according to the requirement. Once the model is printed, it is cleaned and can be hardened using UV light. Moreover, the colour can be adjusted as per the wish by painting.

Final Words

Inarguably, rapid prototyping has emerged as a fundamental need of multiple industries. The same is the case with the architectural industry. Suppose you are looking for a reliable source that could help you with state-of-the-art rapid prototyping of your architectural designs or structures. In that situation, ArpTech remains a valuable and cost-effective source. We can add value to the whole process, meeting high-quality standards and without compromising the strength. Likewise, we help create rapid prototypes for engineering verification, sales, and visualising architectural concepts.