Using Rapid Prototyping in the Mining Industry

The industrial sectors all across the globe are rapidly growing, making use of newer and better technologies. These novel technologies are more efficient at getting the job done while replacing conventional methodologies and machinery for the better. One such technology set to revolutionise the industry is rapid prototyping. It may have made a strong presence in the healthcare, aerospace, automotive, robotics, and even agricultural sector. However, today, our focus will be on using rapid prototyping in the mining industry. Although we will also discuss the applications and impacts of rapid prototyping in the mining industry, let us start our discussion with the benefits.

Benefits of Using Rapid Prototyping in the Mining Industry

Using rapid prototyping in the mining industry, in particular, presents significant benefits to the entire industry. It makes the work of the mining sector both more straightforward and accessible, while increasing the efficiency of processes by cutting downtime on several tasks. Today, we will be looking into a few advantages presented by using rapid prototyping in the mining industry.

1. Supply Chain Management.

By using rapid prototyping in the mining industry, parts can get manufactured at or near mining sites, i.e., in-house or on-site. In recent times, Anglo-American has joined forces with CSIR (South African Council for Scientific and Industrial Research) and a US-based technology company to support supply chain effectiveness. They intend to explore opportunities to digitally allocate spare parts for mining and processing equipment manufactured in the vicinity utilising 3D printing.

Essentially, rapid prototyping is helpful in several ways. For instance, it is instrumental and efficient when mining sites are located far from the supply chain. This cuts downtime and transport costs utilised to bring a new set of parts when needed. Mines cannot bear interruption, and mere hours can bring about many dollars in misfortunes. Apart from that, managing excess inventory, combined with the expense of warehousing and storage, is also a problem solved by rapid prototyping. Consequently, it helps run a mining operation effectively.

2. Better Tools for Mining.

Unlike standard practices, several tools and materials made using rapid prototyping in the mining industry are more efficient. One such example is the industrial-grade diamond composites used as wear-resistant tools. They are 3D-printed to suit industrial cutting, grinding, drilling, and polishing. Besides, CNC machining can also produce quality tools and materials recurrently and reliably.

3. Readily Available Protective Gear.

Large-scale personal protective equipment (PPE) is one of the most significant present-day applications of 3D printing and rapid prototyping technologies. The application itself is not mining-specific. Nevertheless, it assists frontline mine workers by providing protective gear. It may include hard hats, hearing protection, protective eyewear, and respirator masks.

4. Infinite customisability.

Spare parts and tools are designed in CAD before being finalised for production, more precisely, small-batch production. It allows for an endless range of spare parts and tools customisation, best suited to a particular mining environment. Likewise, components are easier to replicate, as the computerised library of 3D models can be accessed and made available when needed.

5. An Eco-Friendly Process.

Rapid prototyping proves to be an eco-friendly process by being both material and energy-efficient. It is much better and safer for the environment than conventional processes. For example, 3D printing is an additive layer manufacturing process that eliminates the waste of material and energy resources – a hurdle that rapid prototyping overcomes.

Applications of Rapid Prototyping in the Mining Industry

The process of rapid prototyping in the mining industry holds several applications, from conventional ones to specialised applications where rapid prototyping techniques have proved revolutionary. Along these lines, some of these applications are entailed below.

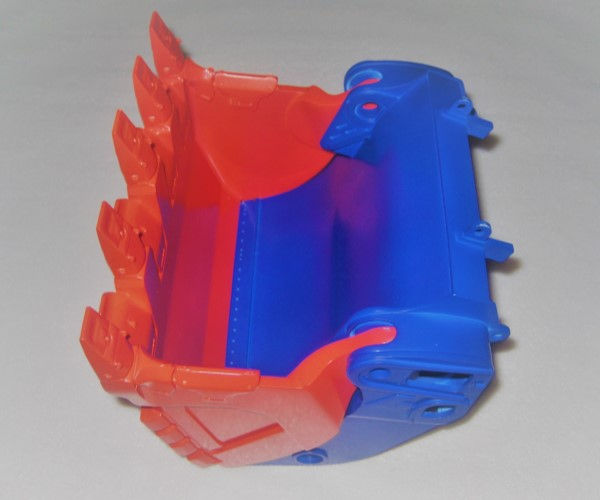

Rapid prototyping serves to develop prototypes, tools, and equipment parts, mainly for replacing and repairing components used in the mining industry. Numerous mining companies, including BHP, Rio Tinto, and Fortescue Metals Group, have also invested and put resources into 3D printing to produce spare parts. Substitutes for exhausted or imperfect components can be delivered, rather than waiting for the OEM to redesign. Similarly, several types of parts can be CNC-manufactured for use in the mining and quarrying industry. These parts may involve gear blanks, shafts, gearbox housing, and bearing seals.

Rapid prototyping provides an accurate 3D topographic maps or outlines of mining sites (shafts, tunnels, etc.). These 3d scaled models are more effective than 2D maps as they capture all the geographical and topographic terrain. Ultimately, it allows miners and engineers to observe, study, and prepare the high-end visualisation to understand the geological terrain and structures.

The foundry patterns, which are used for metal casting, are commonly produced by 3d-printing or CNC machining. As the mining equipment parts are large, therefore patterns can be machined out of lightweight materials such as plastics, chemical wood or epoxy tooling boards.

Rapid prototyping can also be used to mass-produce drones for several purposes, such as safety monitoring of mining sights, surveying, mapping the location, stockpile management, and tailing dam management.

Final Words

Rapid prototyping has stood out in every industry as a revolutionary technology, the same for mining. It is bound to revolution by altering processes in an era when resources are getting scarcer. A high demand exists for newer methodologies that are more flexible, customisable, and volatile. Indeed, recent media coverage proposes that the mining industry is taking 3D printing to a higher level by investigating the utilisation of 3D printers to empower deep-space asteroid mining.

How May We Help You?

Suppose you wish to acquire services or solutions regarding rapid prototyping in the mining industry. In that case, the best option at hand is none other than Arptech. Based in Australia with a success of 90% returning customers, ArpTech is unmatched when it comes down to high-quality and cost-effective rapid prototyping processes. Therefore, be sure to hit us up on our website to place your order or get answers to any queries or questions. We hope to see you soon.